Technology

Separation by Inertia. How does it work?

Filtration is not restricted to capturing particles with a succession of wider to smaller meshed apertures. Our ingenious filters use another principle: separation by inertia.

The migration phenomenon is common when slowdrying coatings are used in combination with mesh or fiberglass filters. This happens when the airflow pulls out particles previously trapped in the mesh or fiberglass. Consequently, the once deposited particles will again migrate throughout the system.

However, with the Andreae Filter Separation by Inertia principle, the paint particles stay trapped in the retention pocket outside of the airstream.

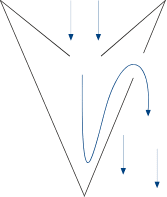

Airflow loaded with paint particles (overspray) will suffer several radical changes in direction. These paint particles, heavier than air, follow

tangent trajectories within the airflow. Thus, paint particles which accumulate in our retention pockets, outside of the air stream, allow the airflow to exit the filter virtually free of any overspray. As a result, our renowned high holding capacity filters hold up to 5 times more than common mesh filters.

Consequently, the static pressure within the booth increases slowly. This has two main advantages; the spray booth stays cleaner longer and the airflow around the coated parts stays uniform throughout the life of the filters.

1. Airflow

Airflow enters the retention pockets and travels all the way through the twists and turns of the unique design of our accordion filter.

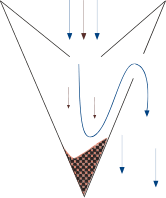

2. Overspray

The paint particles which are heavier than air, follow tangent trajectories within the airflow and gradually accumulate in the retention pockets outside of the airflow.

This eliminates the migration phenomenon inherent to fiberglass and mesh type filters.

3. Paint Deposit

The paint deposits accumulate in voluminous retention pockets, as well as on the side and front of the filter.